In the heart of Kaiserslautern, October 2023 witnessed a convergence of brilliant minds at the BaSyx Digital Twin hackathon (BaSyx Hack), hosted by Fraunhofer IESE. Creativity was in the air, keyboards clicked in a rhythm of innovation, and minds raced against the clock to embrace the challenge. The challenge was clear and formidable: bridge the gap between cutting-edge medical therapies, such as personalized cancer treatments, and the manual processes that hinder their widespread adoption. The quest for automation and digitalization in the medical domain unfolded as interdisciplinary teams embarked on a journey to reshape the future of healthcare.

The challenge: Bridge the gap between cutting-edge medical therapies and their manual manufacturing processes

Addressing the gap between cutting-edge medical solutions and their universal accessibility is a pressing concern in the healthcare system. Emerging advancements pose the challenge of overcoming costs and technological limitations to produce such medicines on a large scale. Technology and research are key drivers in closing this gap, aiming to make state-of-the-art treatments not just a privilege for a few but a reality for the many, thus fostering a more inclusive healthcare system for all.

In recent years, Advanced Therapy Medicinal Products (ATMPs) have emerged as groundbreaking medicines for the treatment of cancer, genetic disorders, and degenerative conditions. Such innovative therapies have been showing outstanding efficiency and results. Unlike traditional pharmaceuticals, the manufacturing of ATMPs uses a highly complex and personalized approach to modify messenger-RNA in order to achieve the desired therapeutic effects. The manufacturing of ATMPs is, however, still a pressing concern since it mostly relies on very meticulous and manual work that ends up drastically increasing the manufacturing costs, as traditional approaches for automation are not feasible in this area.

A promising solution for reducing costs is the use of technologies such as Digital Twins, which offer the capability required to manufacture goods for the so-called “lot size 1”. In the medical domain, this would be a therapeutic product highly individualized for one specific patient – which is exactly what ATMPs are designed for.

In a nutshell, participants of the BaSyx Hack were tasked with envisioning digitalization ideas tailored to the distinctive hurdles encountered in the manufacturing, transportation, and assessment of ATMPs. The core of the challenge lay in exploring how Digital Twins, a cutting-edge technology, could revolutionize the manufacturing of individualized medical products, particularly in the realm of cancer therapies.

The focus was on leveraging Digital Twins to pave the way for groundbreaking solutions. Digital Twins – virtual replicas of physical entities or processes – have already shown immense promise in various industries. However, our hackathon posed a fascinating question: How can we employ Digital Twins to revolutionize the manufacturing of personalized medical treatments?

The catch was that participants didn’t need any encyclopedic knowledge of medicine. Instead, the emphasis was on encouraging creative thinking and cross-disciplinary collaboration. We wanted teams to bring fresh perspectives to the table, transcending traditional boundaries and reimagining the possibilities.

The overarching goal was crystal clear – to make personalized therapy accessible to a broader population. With cancer therapies as a prime example, participants were challenged to think beyond conventional methods. The solutions sought were not confined to laboratories and medical journals; they were rooted in the innovative application of digital technologies.

Dedicated participants: 13 teams were formed at the event and worked on the challenge

The hackathon was composed of 13 dedicated teams that embarked on a journey of innovation. These clever participants did not let the lack of medical background knowledge stop them. They came up with impressive ideas and delivered working prototypes to prove their concepts.

From inventive solutions targeting the optimization of pharmaceutical logistics to the seamless integration of robotics with Digital Twin controls, the diversity of approaches was nothing short of impressive. Some teams delved into the realm of automated documentation, envisioning a future where paperwork hurdles in personalized medicine could be navigated effortlessly. Others took a collaborative approach, forging innovative pathways to enhance partnerships among stakeholders in the ATMP ecosystem.

As we celebrate the winners and their outstanding contributions, let us also recognize the teamwork and commitment that filled every part of the hackathon space. While the competition has concluded, the influence of these ideas will extend well beyond the event, making a lasting impression on the field of digital healthcare innovation.

In the following, we will present the ideas of the champions: These three winning teams demonstrated inspiring ideas and technical astuteness.

1st place BaSyx Hack: Team „Clean Room“ – Digital Twin to access lab equipment

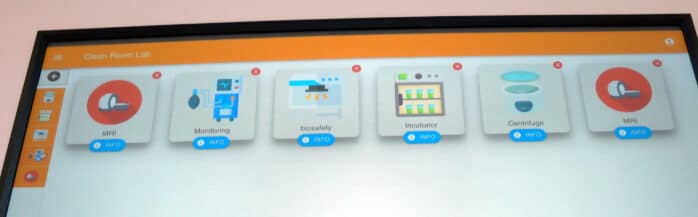

The proposed approach applies Asset Administration Shells (AAS) for laboratory equipment using an AI model. AAS are established using equipment specification sheets that form a centralized database of pre-designed Digital Twins. This method offers lab managers a straightforward way to choose and implement these Digital Twins, streamlining equipment management via an intuitive drag-and-drop interface. The challenges in lab equipment management, such as the intricacies of setup and management, are addressed by this solution, which aims to provide accessible and efficient management options.

Using an AI-driven system, the proposed solution generates AAS for lab equipment by referencing equipment specification sheets. This process results in a library of predefined AAS templates for diverse lab equipment, ready for deployment based on specific laboratory needs. These templates are accessible via a central hub, empowering lab managers to select and utilize Digital Twins effortlessly. The drag-and-drop interface further simplifies equipment configuration, enabling customization to meet precise requirements.

Key advantages:

- Efficient equipment setup: The predefined AAS templates simplify and speed up setting up lab equipment, reducing the time and effort required by lab managers.

- Consistency in configuration: The use of predefined templates ensures consistency in the configuration of lab equipment, minimizing errors and enhancing overall operational efficiency.

- Flexibility for lab managers: Lab managers gain the flexibility to choose from a wide range of predefined Digital Twins and can tailor their selections to match the diverse needs of the laboratory.

2nd place BaSyx Hack: Team „Rathi“ – Digitalize lab equipment setup

This approach integrates Augmented Reality (AR) glasses, Digital Twins, and Artificial Intelligence (AI) models to streamline lab procedures, aiming to minimize manual labor and enhance the efficiency of complex tasks in laboratory environments. It addresses challenges related to intricate experiment setups by employing AR glasses for process recording and commands, Digital Twin templates to standardize experiment configurations, and an AI model translating experiment requirements into audio instructions delivered through AR glasses to guide lab workers through setup processes. Additionally, real-time monitoring using Machine Learning (ML) models ensures the accuracy and integrity of ongoing experiments.

The proposed solution addresses current challenges in lab experimentation and also lays the groundwork for future advancements where AR and Digital Twins will be central to optimizing laboratory workflows. It showcases the potential of advanced technologies to revolutionize complex processes, offering a glimpse into a future where manual labor in lab setups will be substantially minimized through seamless integration of AI and AR technologies, thereby transforming the landscape of laboratory operations.

Key advantages:

- Efficiency in experiment setup: AR glasses and Digital Twin templates significantly enhance the efficiency of lab equipment setup, reducing the complexity of tasks.

- Guided experiment execution: The AI model’s audio instructions delivered through AR glasses guide lab workers through experiment steps, minimizing errors and ensuring consistency.

- Real-time monitoring for quality assurance: Machine Learning models perform real-time checks during experiments, providing instant feedback and ensuring the accuracy and quality of the conducted exercises.

- Automated documentation: Voice-recorded results are automatically converted to text, streamlining the documentation process and reducing the manual effort required for record-keeping.

3rd place BaSyx Hack: Team „Process My Sample“ – Labs Digital Twin

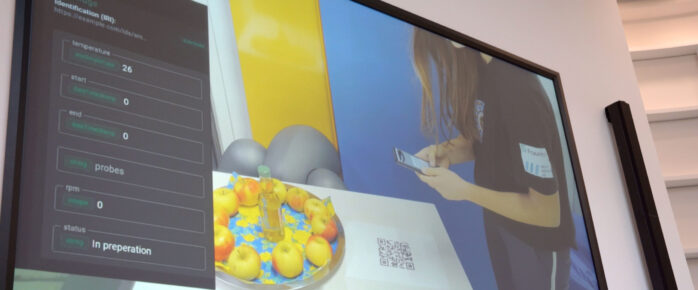

The proposed solution centers around establishing a Digital Twin for laboratories and is aimed at streamlining workflows and facilitating efficient data transfer. By creating a digital replica of the physical lab environment, the solution optimizes processes and analyses and serves as a centralized platform for various operations. It emphasizes the use of QR code-based communication to enable seamless data exchange between doctors, laboratory workers, and other stakeholders, fostering enhanced collaboration.

The prototype enables an interconnected laboratory ecosystem where Digital Twins play a crucial role in driving efficiency, collaboration, and data-driven decision-making. It signifies a significant leap forward in the digital transformation of laboratories, promising a more connected and streamlined future for healthcare diagnostics and analysis.

Key advantages:

- Workflow optimization: The Digital Twin serves as a dynamic platform for optimizing various laboratory processes, ensuring efficiency and accuracy in operations.

- Collaboration enhancement: By centralizing sample data and enabling QR code-based data transfer, the solution fosters improved collaboration between doctors and laboratory personnel. This not only streamlines communication but also enhances the overall quality of patient care.

- Real-time information access: Stakeholders can access real-time information through the Digital Twin, allowing for prompt decision-making and reducing delays in the analysis and reporting of results.

A collaborative network of partners amplified the BaSyx Hackathon success

The success of the event was enhanced thanks to the support from valuable and cooperative partners of Fraunhofer IESE and the BaSys Hack that share our visions and goals towards a digitalized future. Thus, we want to express pecial thanks to:

Sparkasse Kaiserslautern

Health and Innovation Hub (HIH)

NetApp

Industrial Digital Twin Association (IDTA)

Hackathon epilogue: Eclipse BaSyx and the intriguing journey into what comes next

The Eclipse BaSyx Hackathon was not just an event; it was a convergence of brilliance, creativity, and the pursuit of innovative solutions. Hosting this hackathon was an absolute delight, and the enthusiasm and energy brought in by the 13 participating teams added an extra layer of excitement. As we reflect on the incredible journey we have embarked on, from the ideation phase to the culmination of functioning prototypes, it is evident that the Eclipse BaSyx Hackathon was more than just a competition— it was a big creative force towards a purpose.

The fun we had hosting the Eclipse BaSyx Hackathon was immense, and the sheer joy and excitement among the participants added an extra layer of vibrancy to the event. From spirited discussions to the prototype presentations charged with tension, the hackathon was a testament to the power of collaborative ideation. But our journey does not end here. Stay tuned for upcoming events as we delve into the brilliant solutions generated during the Eclipse BaSyx Hackathon. The transformative potential of digitalization in personalized medicine is just beginning to unfold, and the impact on healthcare could indeed be revolutionary.

___________________________________________________________________

This blog-article has been co-created by our Master’s student Vivek Argawal:

Vivek Agarwal is a Master’s degree student of Computer Science at RPTU and has been working as a research assistant in the Virtual Engineering department at Fraunhofer IESE since 2023. Mr. Agarwal is currently working on developing I4.0 components and instantiating applications using the Eclipse BaSyx middleware.