Faster Time-to-Market

Time is money! Often the winner is not who was able to place the best product on the market, but the one who placed it first. In addition to the actual development and implementation, however, it is often tests and troubleshooting that delay completion. Digital Twins realize digital representations of systems as virtual test environments. Changes, the integration of systems, and new developments can be tested in this way. With a Digital Twin, you can also reliably reproduce rare situations, such as hardware defects, operating mistakes, or transmission errors.

Cost savings

It is often difficult to understand how complex systems work. There is a reason why the first steps on the path to Industrie 4.0 are “seeing” and “understanding” one’s own systems. Digital Twins realize a holistic representation of a system. They can merge data from various sources and thus identify optimization potential. These interfaces are also suitable for long-lived systems and therefore enable lasting access to data from different sources.

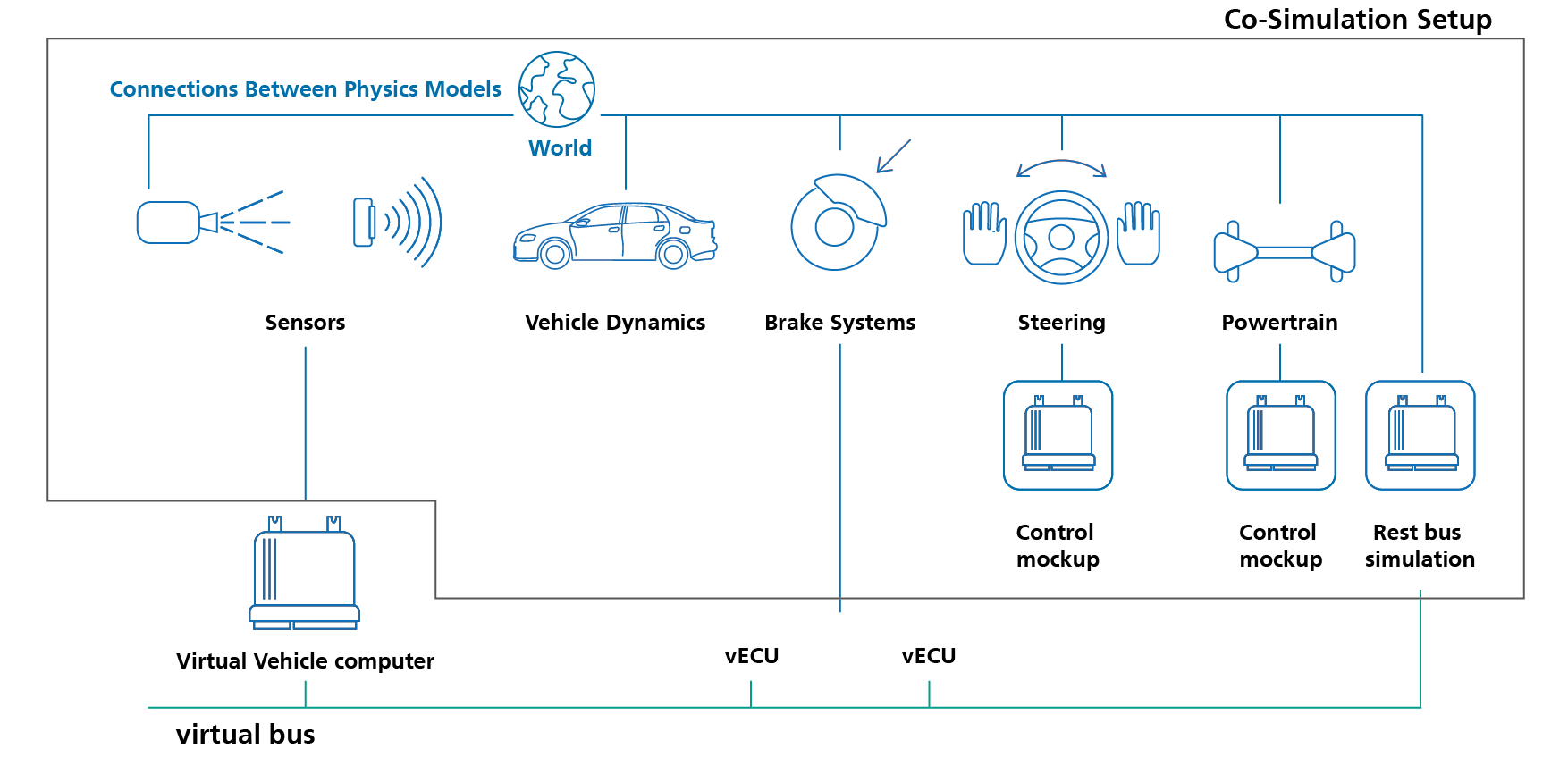

Higher quality

Changes in systems often entail unintended misbehavior, so-called side effects. Digital Twins provide a virtual representation of the target system and its environment and thereby enable the establishment of a Continuous Integration / Continuous Engineering environment even for embedded systems. Your system is thus automatically tested with every change, and you can change your software quickly and efficiently and also detect unwanted side effects efficiently.

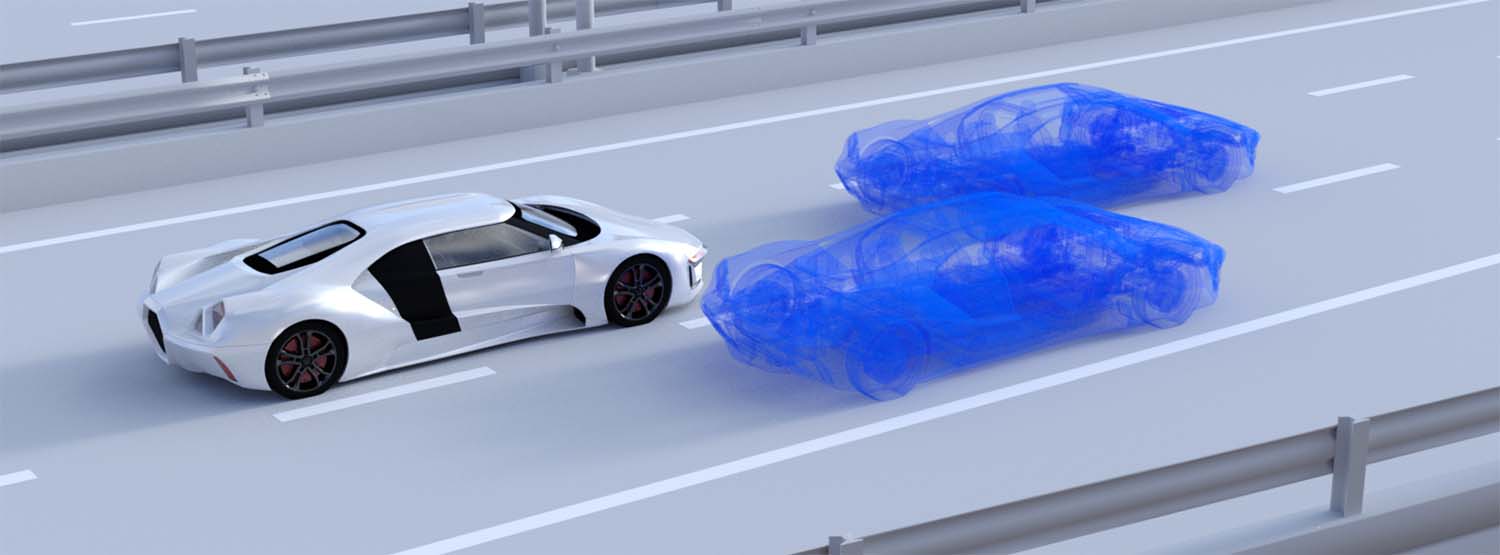

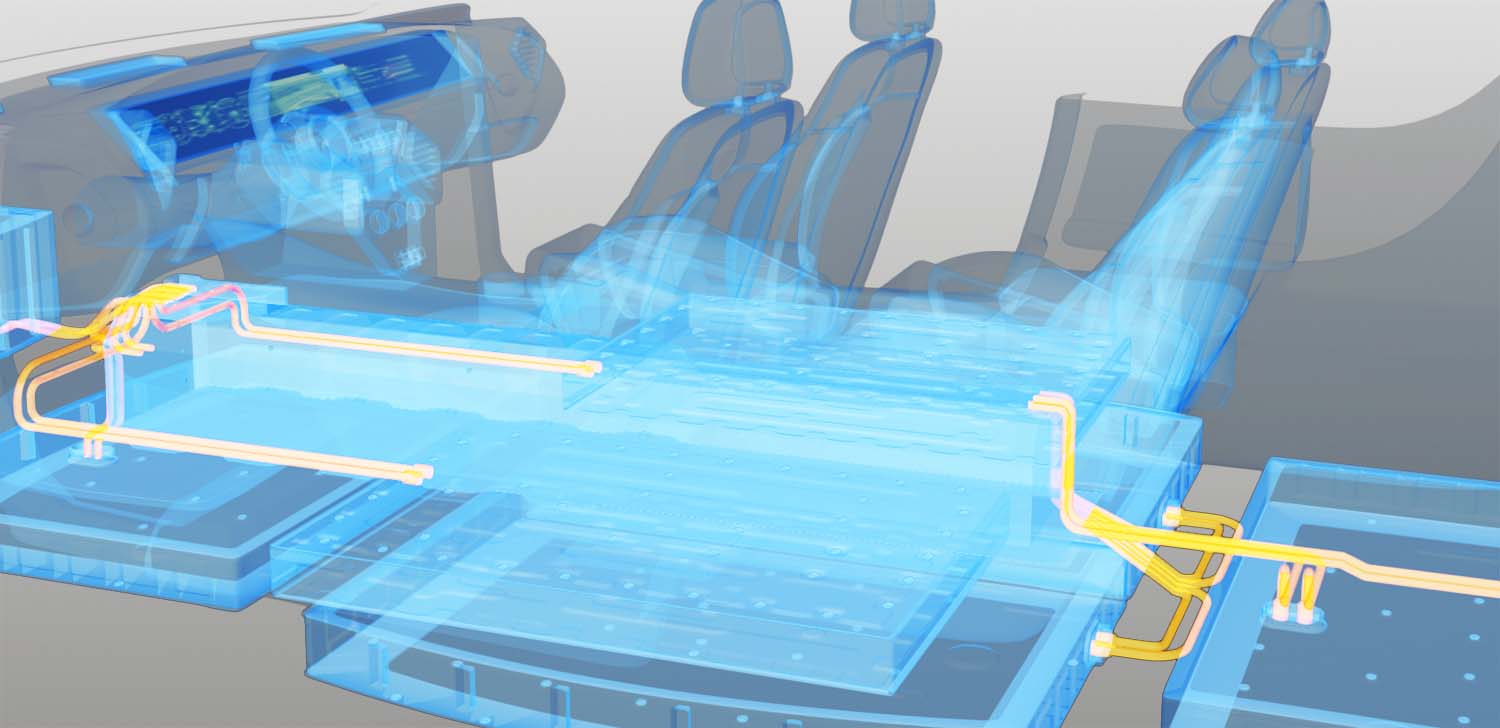

Enabler for autonomous systems

While current systems have only a limited scope for making decisions, autonomous systems, such as autonomous vehicles, make significantly more decisions independently. To make the right decision in the current situation, perception of the environment is necessary. Autonomous systems are therefore often interconnected and share sensor information across physical system boundaries. In these cases, simulations are a prerequisite for quality assurance and safety assurance. We carry out research for you on how to realize self-optimizing systems and autonomous decisions with Digital Twins. Do you want to profit from this research?

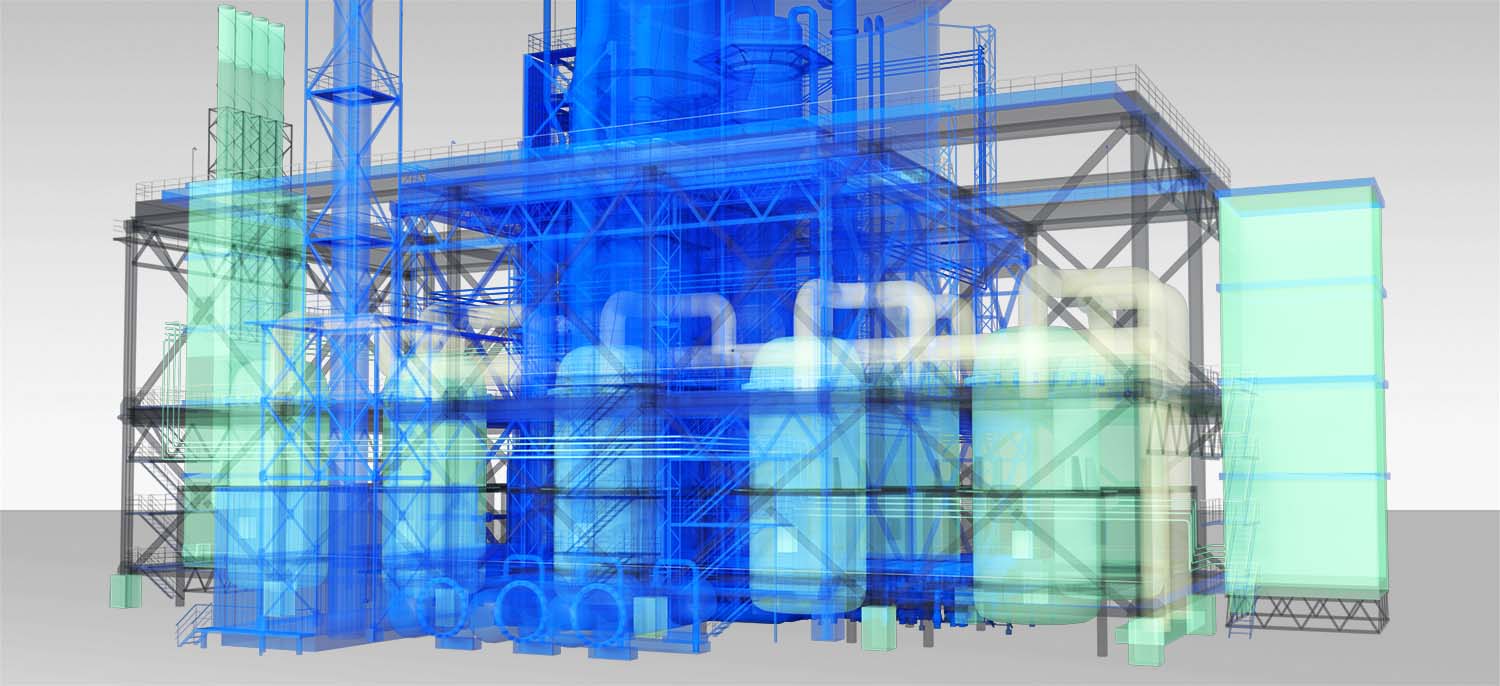

Enabler for Industrie 4.0

Predictive maintenance, which prevents unplanned downtime, is almost an Industrie 4.0 classic. The data required for this is provided by Digital Twins. Technically, this is realized with the help of an asset administration shell and submodels. More complex Industrie 4.0 applications also become possible with Digital Twins. Virtual commissioning shortens setup times, and flexible production can also manufacture small lot sizes in a cost-effective manner. Our open-source Industrie 4.0 middleware Eclipse BaSyx realizes the platform for your digital manufacturing. Contact us!

Back to Overview